SAFETY FACTOR [K]

To ensure necessary transmission safety also under extreme operating conditions adequate safety factor must be considered the value of which depends on operating conditions namely, the type of load, prime mover etc.

Typically [K]

For Electric drive

- Low masses equal loading & non-intermittent operation [2.0]

- Low masses light shock load & intermittent operation [2.5]

- Medium masses, light shock load & intermittent operation [3.0]

- Large masses, light shock load & intermittent operation [3.0]

- Non-overhauling loads [2-3]

- Overhauling loads [3-4]

- Diesel engine drive [4-5]

- Compressor driven [5-6]

However, we recommend you to perform detailed calculations for which please consult us.

Note :

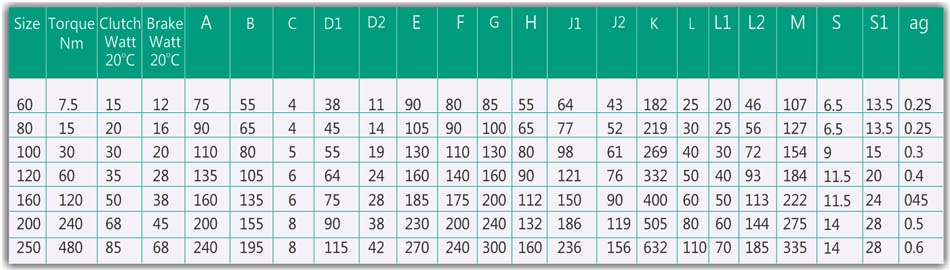

- 1 Nm = 0.012 Kgm = 0.737 Ib-ft = 10.2 kgcm

- Keyways to Indian standard / Din Standard.

- Standard Voltages 24 VDC ; 96 VDC ; 190 VDC ; other voltages on request.

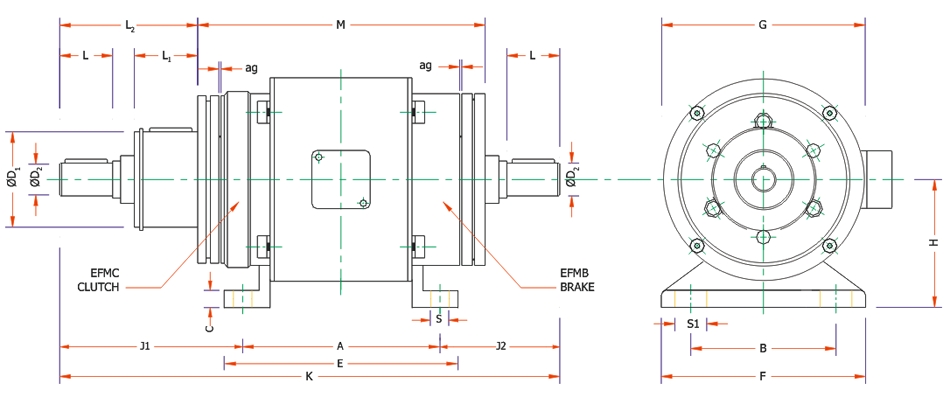

Size Selection And Ordering Information

Approximate necessary Torque or Size of a unit for applications involving low inertia & low operating frequency is determined as ;

TORQUE = [9550 x (K.W. / SPEED)] x SAFETY FACTOR [K]

Ordering Information :