Choosing the Right Brake Motor: A Guide for Industrial Machinery Selection

Indus-tech industrial expo

February 24, 2018Cracking the Code: Understanding the Difference between AC Brake Motors and DC Brake Motors

February 8, 2024Introduction:

In the fast-paced world of industrial machinery, efficiency and reliability are paramount. One often-overlooked component that plays a critical role in the seamless operation of manufacturing processes is the brake motor. As a key element in controlling motion and ensuring safety, selecting the right brake motor is a decision that can significantly impact the overall performance of your industrial setup. In this guide, we’ll delve into the crucial factors to consider when choosing a brake motor, empowering you to make informed decisions for your specific industrial machinery needs.

Understanding the Basics:

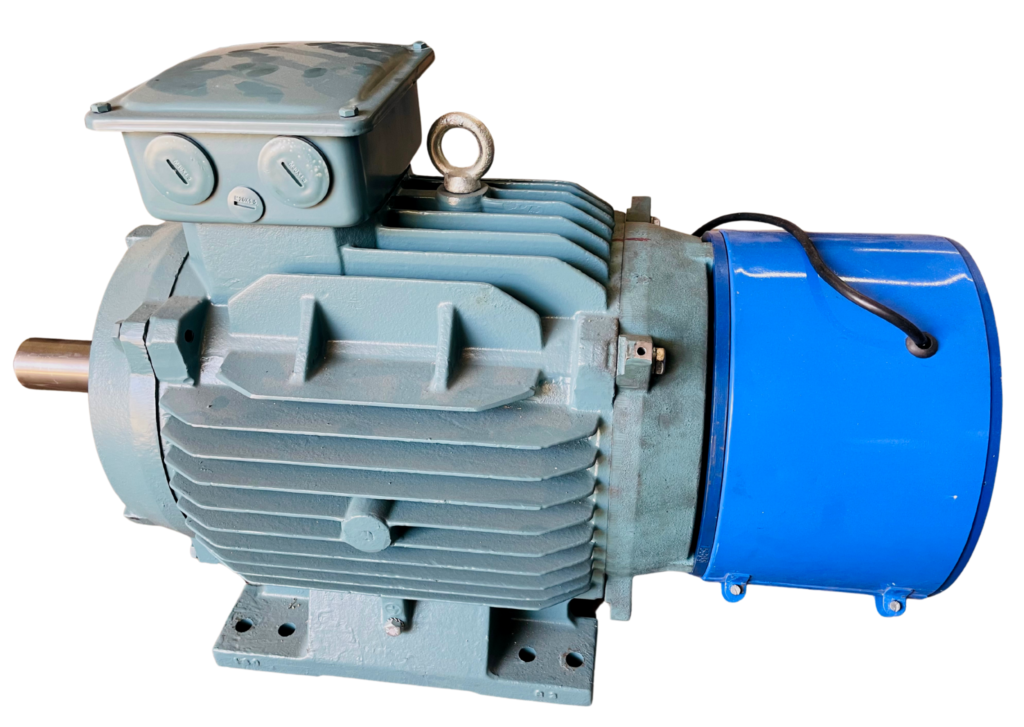

Before diving into the selection process, it’s essential to have a solid understanding of what a brake motor is and how it functions. Brake motors are electric motors equipped with an integrated braking system. This system allows for precise control over the motion of machinery by quickly stopping or holding the motor shaft when power is cut. This feature is especially important in applications where rapid stopping or holding is necessary for safety and operational reasons.

Key Considerations for Selection:

- Application Requirements: Identify the specific requirements of your industrial application. Consider factors such as load characteristics, duty cycle, and environmental conditions.

- Braking System Type: Different applications may demand different types of braking systems, such as electromagnetic brakes or mechanical brakes. Understand the advantages and limitations of each to determine the best fit.

- Motor Size and Power: Select a motor with the appropriate size and power rating for your application. Oversized or undersized motors can lead to inefficiencies and increased operational costs.

- Speed Control and Precision: Evaluate the need for speed control and precision in your machinery. Some brake motors come with variable speed options, providing enhanced control over motion.

- Environmental Factors: Consider the operating environment, including temperature, humidity, and exposure to contaminants. Choose a brake motor with protective features that align with your working conditions.

- Maintenance Requirements: Assess the ease of maintenance and the expected lifespan of the brake motor. Opt for a model that minimizes downtime and maintenance costs.

- Compliance and Safety Standards: Ensure that the selected brake motor complies with industry standards and safety regulations. Prioritize the safety of your workers and the longevity of your machinery.

Conclusion:

Choosing the right brake motor is a critical step in optimizing the performance and safety of your industrial machinery. By considering the specific needs of your application and thoroughly evaluating key factors, you can make an informed decision that aligns with your operational goals. Remember, a well-selected brake motor is not just a component; it’s an investment in the reliability, efficiency, and longevity of your industrial processes.